Implement standards: Q/FCJX 1001-2018 "Vehicle-mounted telescopic arm rotary blade hedge trimming machine"

Three section telescopic arm

Active safety technology

Manual emergency return device

Three-axis inline oblique knife holder

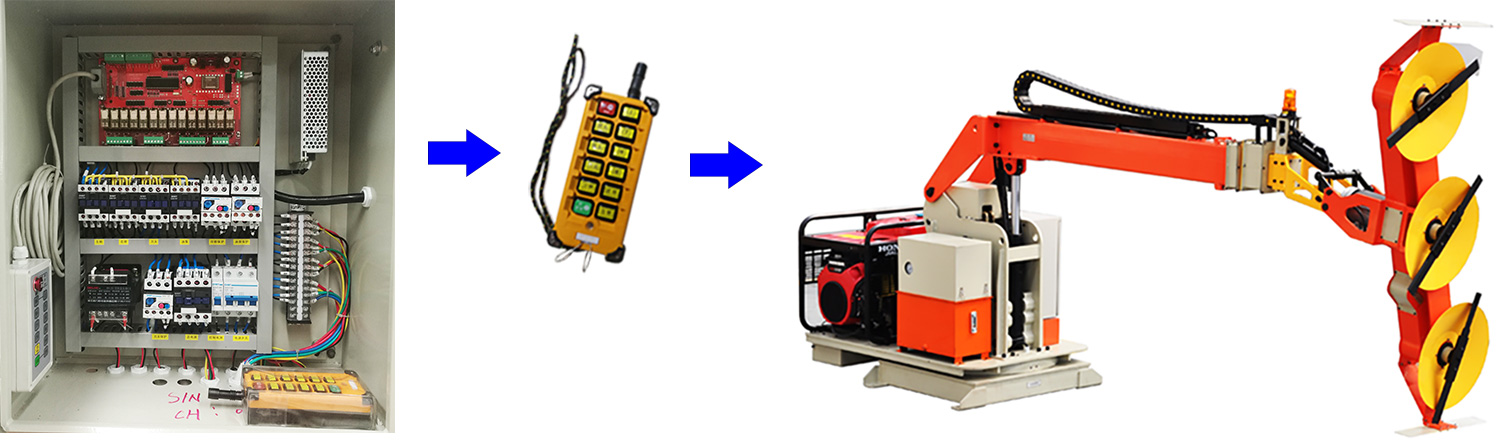

Composite rotating circular saw blade holder

STC microcontroller integrated control system

Modular structure, lightweight design, rigorous attention to detail processing

The combination of orange and yellow tones highlights the leading quality of Equation Machinery

Using a 1.8-ton light truck for carrying, it can trim the median green fence, high branches and thick branches on the right side of the highway

Shrubs and weeds on the right slope, truly achieving multiple uses for one machine

Original composite rotating circular saw blade holder, using two 400mm circular saw bladesExcellent performance, capable of trimming 150mm thick branches and various dense hedgerows

Pioneering three-axis inline oblique knife holder, using three specially made 655mm bladesSeamless pruning adapted to various shrubs and weeds

Powered by a powerful gasoline engine from Briggs&Stratton or Kohler, with an electro-hydraulic hybrid drive,Strong power, meeting the requirements of various high load working conditions

The mainstream models are equipped with three synchronous telescopic arms, which can meet the requirements of mid-range belt trimming and short distance trimming

The requirement for long distance trimming on the right slope is that the maximum arm length is 5.7 meters

The exclusive side shear integrated machine is equipped with a swinging side shear arm and a knife holder.

It is possible to trim both the top and side surfaces of the median hedge at the same time.

Double efficiency and reduce road time by half.

Unique active safety design, the knife holder is in a non workingarea,and the main motor cannot be started

Eliminate the risk of misoperation and ensure job safety

Specially designed emergency return system, in case of power or hydraulic system failure.

Can manually reset the equipment quickly and evacuate the work site.

Equipped with an STC microcontroller integrated control system, operated using an 18 channel handheld.

remote control,Truly achieving effortless control.

Main configuration and technical parameter table

| Components | Items | Parameters | Remarks | |||||

| Generator set | Model | Equation Power BKT3200 | Use Briggs & Stratton or Kohler engine | |||||

| Fuel type | Gasoline | |||||||

| Rated power | ≥15 kw | |||||||

| Power factor | 0.8 | |||||||

| Number of phases | Three phase | |||||||

| Body | Model | GLC Series 160X Special Body | ||||||

| Telescopic arm | Model | 1830 type | ||||||

| Structural type | Three-stage synchronous telescoping | |||||||

| Maximum effective length | 5172mm | |||||||

| Minimum effective length | 2917mm | |||||||

| Expansion stroke | 2260mm | |||||||

| Straight blade holder | Model | 3*180 type | ||||||

| Structural type | Single motor three-axis inline oblique placement | |||||||

| Blade type | 2*650mm+570mm straight blade or diamond blade | |||||||

| Number of blades | 3 | |||||||

| Main motor power | 3kw | |||||||

| Blade shaft speed | 2880rpm | |||||||

| Scanning width | 1800mm | |||||||

| Hydraulic station | Model | 160X-5P Enhanced | ||||||

| Cooling method | Natural cooling | |||||||

| Electronic control system | Model | GLC130XDK type | ||||||

| Type | Single-chip integrated control | |||||||

| Operation mode | 12-channel wireless remote control + wire control | |||||||

| Emergency Return | Model | GLC180YJ-2 type | ||||||

| Overall parameters | Maximum trimming height (reference index) | Flat cutting ≥4300mm/Vertical cutting ≥6000mm | When the height of the carriage plate is 900mm | |||||

| Minimumtrimming height (reference index) | Flat cutting-1436mm | When the height of the carriage plate is 900mm | ||||||

| Trimming distance of main arm | 5725mm | Starting from the equipment rotation center | ||||||

| Trimming distance of main arm | 1785mm | Starting from the equipment rotation center | ||||||

| Elevation angle of boom at low position installation | +11° | |||||||

| Depression angle of boom at low position installation | -36° | |||||||

| Elevation angle of boom at high position installation | +36° | |||||||

| Depression angle of boom at high position installation | -16° | |||||||

| Swing angle of main blade holder | ≥130° | |||||||

| Outline dimensions | 4636/4220mm x 1080mm x 1756mm | |||||||

| Whole machine weight | 1580kg | |||||||

Innovation model, industry pioneer, Yantai equation

Technical Support: +8618562238161、+86-535-6723056 Fax: +86-535-6723056

1. Install and debug the equipment on-site, and provide maintenance, operation, and safety technical training to 2 operators.

2. The warranty period for the entire machine is one year, but the generator and/or engine are covered by the manufacturer's warranty terms.

3. The vulnerable parts specified in the contract and/or manual are not covered by the warranty.